Electrial Earthing System

What is Electrical Earthing or Grounding:

To connect the metallic (conductive) Parts of an Electric appliance or installations to the earth (ground) is called Earthing or Grounding.

In other words, to connect the metallic parts of electric machinery and devices to the earth plate or earth electrode (which is buried in the moisture earth) through a thick conductor wire (which has very low resistance) for safety purpose is known as Earthing or grounding.

To earth or earthing rather, means to connect the part of electrical apparatus such as metallic covering of metals, earth terminal of socket cables, stay wires that do not carry current to the earth.

Earthing can be said as the connection of the neutral point of a power supply system to the earth so as to avoid or minimize danger during discharge of electrical energy.

Why Earthing is Important:

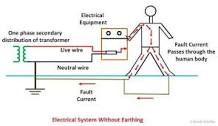

The primary purpose of earthing is to avoid or minimize the danger of electrocution, fire due to earth leakage of current through undesired path and to ensure that the potential of a current carrying conductor does not rise with respect to the earth than its designed insulation.

When the metallic part of electrical appliances (parts that can conduct or allow passage of electric current) comes in contact with a live wire, maybe due to failure of installations or failure in cable insulation, the metal become charged and static charge accumulates on it. If a person touches such a charged metal, the result is a severe shock.

To avoid such instances, the power supply systems and parts of appliances have to be earthed so as to transfer the charge directly to the earth. This is why we need Electrical Earthing or Grounding in electrical installation systems.

Below are the basic needs of Earthing:

To protect human lives as well as provide safety to electrical devices and appliances from leakage current.

To keep voltage as constant in the healthy phase (If fault occurs on any one phase).

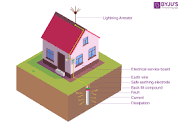

To Protect Electric system and buildings form lighting.

To serve as a return conductor in electric traction system and communication.

To avoid the risk of fire in electrical installation systems.

Terms used in Electrical Earthing:

Earth: The proper connection between electrical installation systems via conductor to the buried plate in the earth is known as Earth.

Earthed: When an electrical device, appliance or wiring systems connected to the earth through earth electrode, it is known as earthed device or simple “Earthed”.

Solidly Earthed: When an electric device, appliance or electrical installation is connected to the earth electrode without a fuse, circuit breaker or resistance/Impedance, It is called “solidly earthed”.

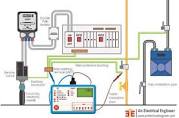

Earth Electrode: When a conductor (or conductive plate) buried in the earth for electrical earthing system. It is known to be Earth Electrode. Earth electrodes are in different shapes like, conductive plate, conductive rod, metal water pipe or any other conductor with low resistance.

Earthing Lead: The conductor wire or conductive strip connected between Earth electrode and Electrical installation system and devices in called Earthing lead.

Earth Continuity Conductor: The conductor wire, which is connected among different electrical devices and appliances like, distribution board, different plugs and appliances etc. in other words, the wire between earthing lead and electrical device or appliance is called earth continuity conductor. It may be in the shape of metal pipe (fully or partial), or cable metallic sheath or flexible wire.

Sub Main Earthing Conductor: A wire connected between switch board and distribution board i.e. that conductor is related to sub main circuits.

Earth Resistance: This is the total resistance between earth electrode and earth in Ω (Ohms). Earth resistance is the algebraic sum of the resistances of earth continuity conductor, earthing lead, earth electrode and earth.

Points to be Earthed:

Earthing is not done anyhow. According to IE rules and IEE (Institute of Electrical Engineers) regulations,

Earth pin of 3-pin lighting plug sockets and 4-pin power plug should be efficiently and permanently earthed.

All metal casing or metallic coverings containing or protecting any electric supply line or apparatus such as GI pipes and conduits enclosing VIR or PVC cables, iron clad switches, iron clad distribution fuse boards etc should be earthed (connected to earth).

The frame of every generator, stationary motors and metallic parts of all transformers used for controlling energy should be earthed by two separate and yet distinct connections with the earth.

In a dc 3-wire system, the middle conductors should be earthed at the generating station.

Stay wires that are for overhead lines should be connected to earth by connecting at least one strand to the earth wires.

We carry out Electrical Earthing installation, Troubleshootings and Maintenance. We have the technical competency and integrity to efficiently design, undertake and deliver Electrical Earthing installation of any kind and magintude.Call on us for your Electrical Earthing solution at ESAR-Engineering Global.